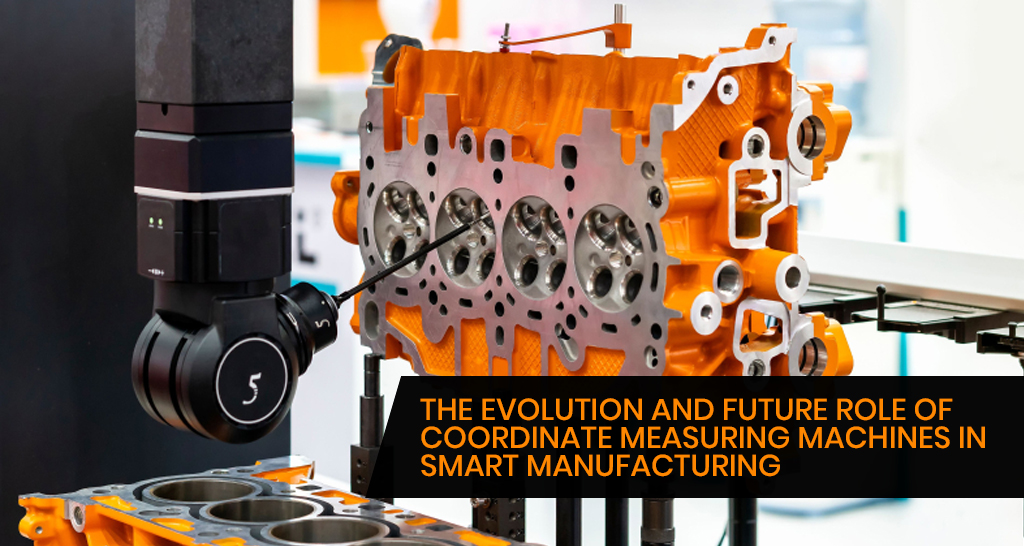

The Coordinate Measuring Machine (CMM) has dramatically changed since it was first made in the late 1950s. Now, it is an essential tool for getting accurate measurements in manufacturing.

Historical Journey of the CMM:

The roots of CMMs trace back to the automotive and aerospace industries of the late 1950s. Before transitioning to touch-trigger probe technology, earlier machines relied on hard probes in the 1960s. Integrating digital computers in the same period marked a significant milestone, enabling more accurate and efficient data processing. Companies like Digital Electronic Automation (DEA) played a pivotal role in the CMM’s evolution.

In the 1970s, advancements such as 3-D scanning and automatic sensor change racks enhanced measuring capabilities. In the 1990s and 2000s, the introduction of automated data collection, improved software, and multi-sensor capability led to widespread adoption across industries. Industry standards, like ISO 10360, were established to guide CMM accuracy and performance.

CMM in Smart Factories:

The emergence of smart factories, driven by technologies like IoT, AI, and Big Data analytics, has made CMMs’ role even more critical. These machines provide real-time data on the physical dimensions of parts, contributing to improved efficiency, flexibility, and quality in manufacturing processes.

In smart factories, CMMs are essential for quality control. The data generated aids in identifying design and manufacturing process improvements, leading to increased efficiency and reduced waste. Additionally, CMM data optimizes the supply chain by offering real-time information on part availability, minimizing disruptions.

Model-Based Definition (MBD) in CMM Programming:

CMM programming is an emerging trend with something called Model-Based Definition (MBD). MBD uses a 3D digital model to define a part’s geometry and tolerances, guiding automated measurement sequences. This approach enhances accuracy, efficiency, and flexibility. It also makes it easier for people to work together and track what’s been done.

MBD benefits include improved accuracy, increased efficiency through faster setup and analysis, enhanced collaboration among stakeholders, increased flexibility to accommodate design changes, and enhanced traceability between design and measurement data.

Future of CMMs in Smart Manufacturing:

CMMs play a vital role in the future of smart manufacturing. AI and IoT will offer real-time monitoring and control, predictive maintenance capabilities, and automated quality inspection when working together. Digital twin technology will enable virtual testing and simulation, reducing the need for physical testing and enhancing overall efficiencies.

The continuous evolution of CMM technology, combined with integration into Industry 4.0 initiatives, positions these machines as essential tools for increasing efficiency, flexibility, and quality in manufacturing processes. Their ability to provide precise measurements aligns with the broader goal of creating smart factories that are adaptive and efficient.

Machine Integration for Enhanced Efficiency:

Machine integration becomes imperative to fully leverage the capabilities of CMMs and other manufacturing systems. Connecting manufacturing equipment to shop floor systems like MES or ERP enables real-time data collection and analytical capabilities. This integration unlocks the full potential of systems, allowing for automation and informed decision-making.

Machine integration benefits include accurate cycle times for production scheduling, real-time data for quality control and maintenance, and streamlined data flow across various systems. Production monitoring platforms like MachineMetrics enhance the actionability and value of machine data.

Impact of Industry 4.0 on Metrology and Manufacturing:

Industry 4.0 is set to revolutionize manufacturing, potentially adding trillions to the global economy. Smart factories, driven by automation and high-level communication technologies, will significantly impact metrology and quality control. The concept of “smart measurements” using automated processes is expected to revolutionize production by enabling self-correction in case of errors.

Role of Portable CMMs in Industry 4.0:

Portable Coordinate Measuring Machines (PCMMs) are vital in Industry 4.0. These machines enable real-time measurements on the shop floor, allowing for immediate analysis and comparison with CAD files. With the advent of Industry 4.0, PCMM data can be connected across machines and factories, promoting data sharing, reducing waste, and improving productivity.

In conclusion, the journey of Coordinate Measuring Machines (CMMs) from their early days to the present has been continuous innovation and adaptation. In the period of Industry 4.0, CMMs are not just tools for measurement but integral components of smart manufacturing, contributing to real-time decision-making, predictive maintenance, and overall process optimization. As manufacturing continues to evolve, CMMs will remain important, ensuring precision, accuracy, and efficiency in producing high-quality components and products.

Discussion about this post